Aerospace Brazing Service

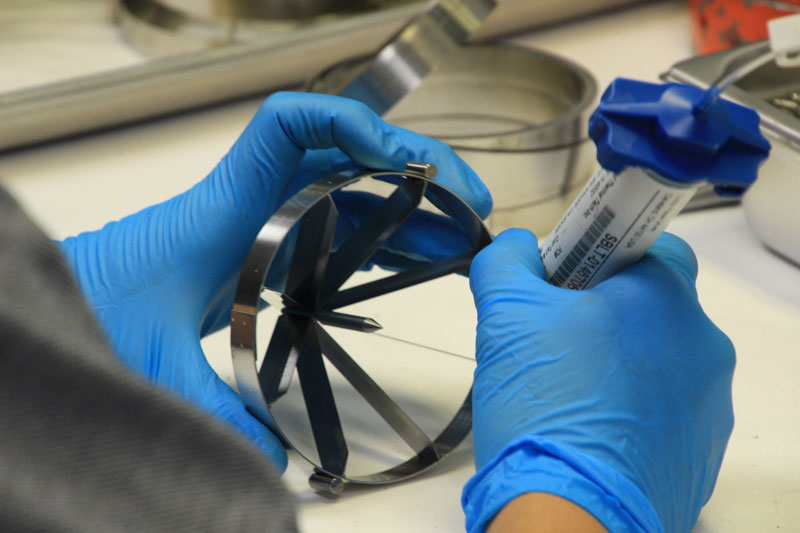

Aerospace brazing is known for super alloy components used in aerospace applications as they are typically joined together by brazing or diffusion bonding with nickel and cobalt base filler metals containing melting point depressants such as boron and silicon. Aerospace brazing services is carried out in high vacuum furnaces by holding the parts for a long period of time to diffuse away boron and silicon. During the aerospace brazing process, our vacuum furnaces can reach temperatures of 2800 degrees F and have vacuum levels of 10-6 Torr, all-metal hot zones, and extremely rapid cooling. Applied Thermal Technologies Inc. personnel work closely with each customer in determining their particular requirements and are available for technical assistance for your aerospace brazing, metallurgy, and heat treating questions.

NADCAP Accreditated in Aerospace Brazing Services:

Applied Thermal Technologies Inc. is your NADCAP accredited metal processing company specializing in vacuum heat treating, ceramic brazing, bright annealing, and brazing of aerospace and medical device stainless steel, titanium, nickel, and other exotic alloys. We started servicing the medical device and specialty products industries in 1992 by offering bright annealing, sintering, and brazing services for medical devices, and aerospace stainless steel, titanium, nickel, ceramic, and other metals.

For the aerospace and medical device industries; sintering and ceramic bright annealing are done using our industrial furnaces feature temperatures of 2800°F, levels of 10-6 Torr, all-metal hot zones, and cooling. Several brazing techniques are applicable to titanium, stainless steel, and carbon steel components where we utilize nickel and low-temperature brazing alloys. Our personnel works closely with you to determine your particular requirements for heat treating or sintering your titanium, nickel, ceramic and bright annealing parts.

For more information on our aerospace brazing services, contact us today!