Vacuum Heat Treatment & Specialty Steel Tempering Services

Vacuum Heat Treatment & Specialty Steel Tempering Services

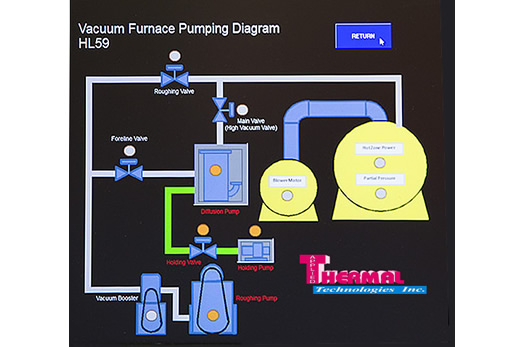

Vacuum Heat Treating and Specialty Tempering services for meeting the needs of the Medical, Aerospace, Food Sector, and Injection Mold industries. Applied Thermal Technologies has equipment for 2800°F, vacuum levels to 10-5 Torr, all-metal hot zones, and variable speed cooling. If you don’t see the material or process you are looking for, use our Contact Us page and our personnel will assist you. We’ll also be more than happy to help answer any questions you may have on our vacuum heat treatment services and our specialty steel tempering services.

Applied Thermal Technologies is ready and capable to validate any service or process we offer to meet the needs of our customers. Our validation engineers are available to work with you on developing a validation for the medical and aerospace sector.

With changing markets comes changing processes. Applied Thermal Technologies added water quenching capabilities for Titanium to meet aerospace needs.

10 vacuum furnaces ranging in size from 18″W x 34″D x 18″H, 600 LBS capacity to 36″W x 48″D x 36″H, 3000 LBS capacity.

1 air furnace 12’ x 3’ x 3’ up to 1450F making it perfect for aging of all PH steels like 17-4, 455, 465, 13-8, 15-5, Inco718, and A286, and Titanium (MIL-H-81200), 10,000 LBS weight limit.

SUPPORT EQUIPMENT

8 tempering furnaces, LN2 Freezer, Calibration equipment to support the requirements of AMS2750 (Pyrometry).

QUALITY SYSTEM

Nadcap™ accreditation is required by many national and international manufacturers and is a mark of prestige that represents superior performance and use of industry standards and leading technology. Nadcap™ accreditation is an important part of the heat treating industry. We are also ITAR registered. We take pride in our accreditations and we know you will, too.

QUALITY

Applied Thermal Technologies is backed by ISO 9001:2015 and AS9100D, and Nadcap™ accreditation which helps us deliver a quality product and service to meet our customers’ needs every time. All processing data is kept in a digital format for future reference and can be supplied to the customer for review at a moment’s notice. All of our accreditations and certificates are available for download or printing from the Quality page.

LEAD TIME

We pride ourselves on lead time and service. Applied Thermal Technologies works hard to achieve an 85% turnaround for most orders in 24 hours on normal business days. When quick turnaround time is desired we will work with customers to decide if expediting is needed.

HANDLING

We treat every order like the part is in the finished state. Each order is hand racked or loaded as to ensure the risk of damage is kept to a minimum. Whether the part is a .001 inch diameter ball or a much larger component part, we use the utmost care, exceeding the customers expectations. One of our greatest compliments is that many of our customers mention how the parts do not even look like they’ve been heat-treated because of how bright and shiny they are.